But construction crews doing work in industrial or office settings often have to lock out and tag a variety of energy sources.

Lock out tag out procedures template ontario.

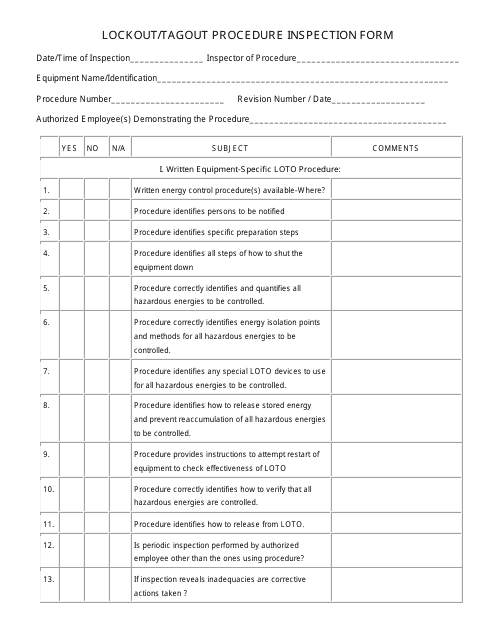

Specific procedures and limitations relating to tagout systems where they are allowed.

Retraining of all employees to maintain proficiency or introduce new or changed control methods.

Lock out and tag out university of ottawa.

Workers executing lockout should have knowledge training and experience relating to these steps and to the sources of energy they are dealing with says mike.

Failure to follow proper lockout tag out procedures may result in disciplinary action up to and.

Osha estimates that complying with loto standards helps prevent 120 fatalities and 50 000 injuries each year.

Forms of energy when most people think of uncontrolled hazardous energy they think of electricity.

Occupational health and safety act of ontario 2.

Examples are coiled springs raised hydraulic equipment and any source energy e g electricity pressurized steam that may cause injury.

Lock out tag out procedures are to be completed before any service or maintenance work on equipment or machinery and or before entry into any grain bin or other area where operating equipment poses a hazard to the entrant.

Or tagout procedures or who works in an area where equipment is being serviced.

3 4 energy control procedures use of lock out tag out equipment to ensure safe work practices.

In the case of a group lockout a designated authorized employee usually the principal.

Establish procedures once you know what you re dealing with create step by step procedures for controlling hazardous energy in your equipment prior to conducting maintenance explains mike.

Additional procedures may need to be developed for other applications that require additional safety measures such as for residual energies.

Time of application of the lock tag.

Why the lockout tag out is required repair maintenance etc.

Osha s lockout tagout fact sheet describes the practices and procedures necessary to disable machinery or equipment to prevent the release of hazardous energy.

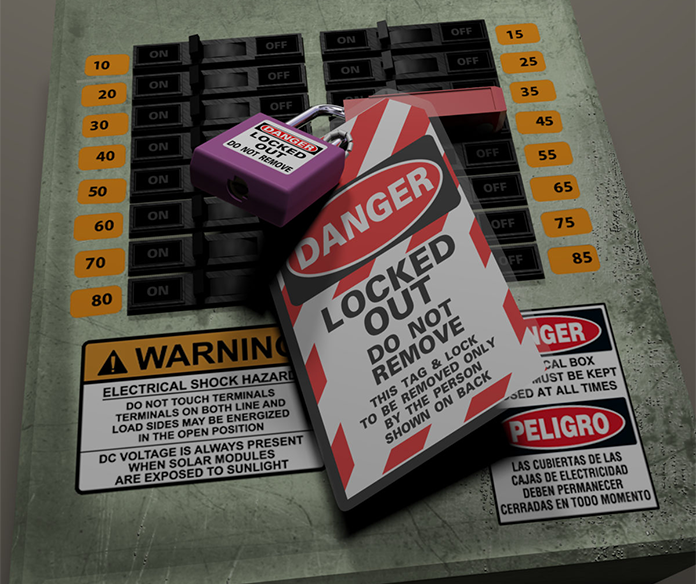

Tags must be attached to each lockout device whether it is a personal lock or a control lock.

Electrical electrical panels generators lighting.

3 5 hazardous motion and energy hazardous motion may result even after power sources are disconnected.

Tag out is a labelling process that is always used when lockout is required.

The process of tagging out a system involves attaching or using an information tag or indicator usually a standardized label that includes the following information.

Authorized employee a person who locks out or tags out equipment to do service or maintenance work.

Applicable legislation guides and policies 1.

The tag should state the name department and telephone number of the person who applied the device the reason for locking out the date and time.

Authority of those named on the tag.

Here are the main types.